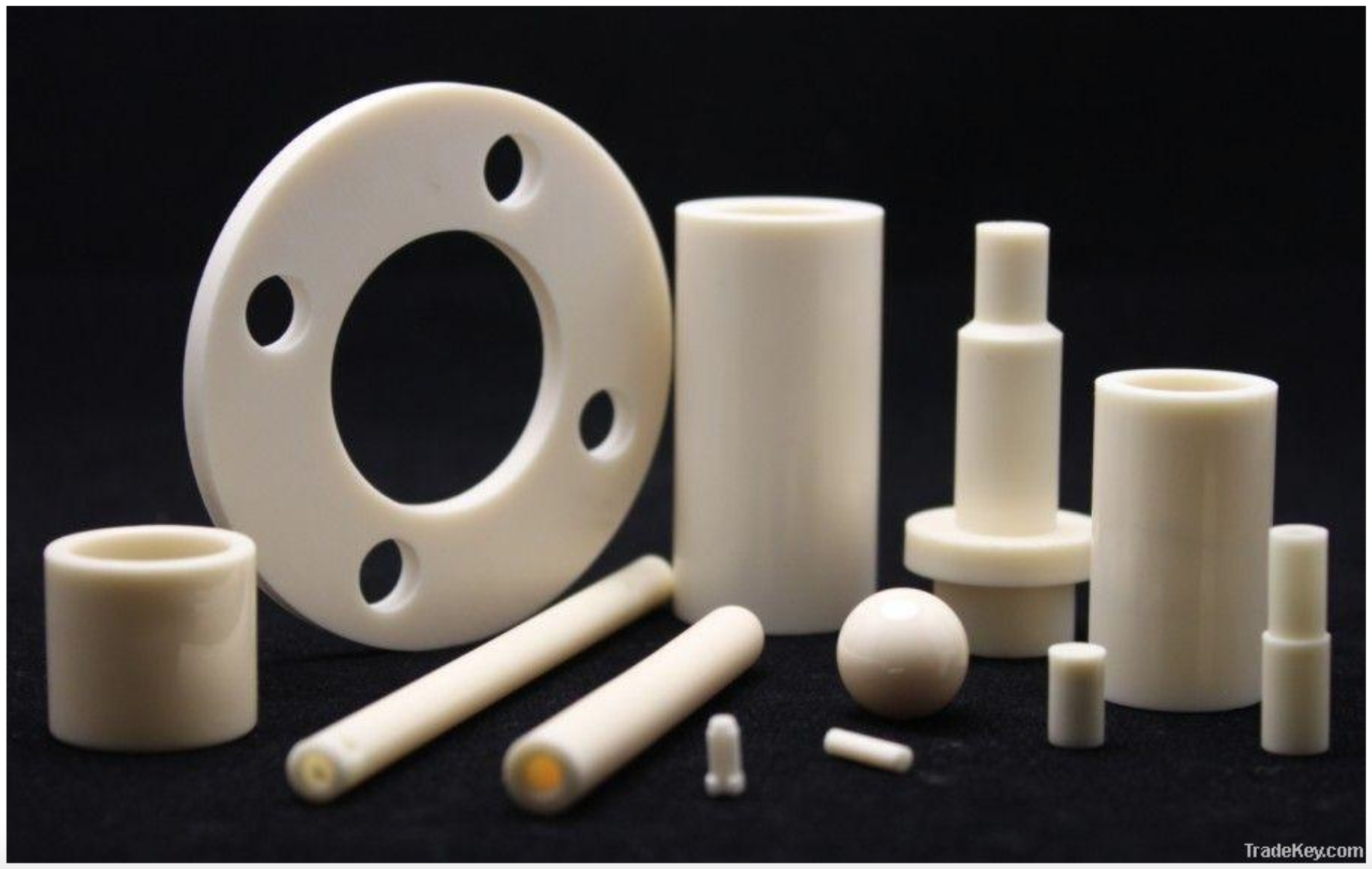

Ceramic bodies and shells are high-performance materials used in metal casting, aerospace, and electronics. They are made from high-purity raw materials, shaped, and fired at high temperatures to form durable, heat-resistant structures. Known for their thermal stability, mechanical strength, and resistance to wear and corrosion, these materials are essential in demanding industries.

Main applications include:

Investment Casting: Ceramic shells serve as molds in investment casting, where molten metal is poured into them to create intricate shapes.

Aerospace: These materials are used to produce turbine blades, nozzles, and heat shields, capable of withstanding extreme stress and temperatures.

Electronics: Ceramic shells protect delicate components from harsh environments and high temperatures.

Refractories: They are widely used in furnaces and kilns, providing the heat resistance required for industrial processes.

Due to their strength, stability, and versatility, ceramic bodies and shells play a crucial role in precision manufacturing and high-performance applications.