Ceramic Bodies & Shells

Instant Reply (whatsapp) +86 137 8230 9705

Ceramic Bodies & Shells

Ceramic Bodies and Shells are high-performance materials widely used in industries such as metal casting, aerospace, and electronics. These materials are crafted from high-purity raw materials, shaped into desired forms, and fired at high temperatures to create durable, heat-resistant structures. Known for their excellent thermal stability, mechanical strength, and resistance to wear and corrosion, ceramic bodies and shells are essential in demanding environments where performance is critical.

Main Applications of Ceramic Bodies and Shells:

- Investment Casting: Ceramic shells are commonly used as molds in investment casting. In this process, molten metal is poured into the shell to create intricate shapes, making them ideal for precision parts used in aerospace, automotive, and industrial applications.

- Aerospace: Ceramic materials are crucial in the aerospace industry. They are used to produce components such as turbine blades, nozzles, and heat shields that can withstand extreme stress and high temperatures, ensuring reliability and safety in aircraft and spacecraft.

- Electronics: Ceramic shells protect sensitive components from harsh environments and high temperatures. They are often used in the manufacturing of semiconductor components, sensors, and connectors to ensure operational stability in challenging conditions.

- Refractories: Ceramic bodies and shells are extensively used in refractory applications, such as lining furnaces and kilns. Their exceptional heat resistance makes them essential for industrial processes that require high-temperature operations, such as metal smelting, glass manufacturing, and cement production.

Due to their strength, stability, and versatility, they are indispensable in precision manufacturing and high-performance applications. These materials support the integrity and longevity of critical components across various industries, contributing to the efficiency and safety of industrial operations.

Key Materials: Brown Fused Alumina, White Fused Alumina, Black Silicon Carbide, and Green Silicon Carbide are often used in ceramic bodies and shells. These abrasives are valued for their high durability, resistance to thermal shock, and ability to withstand extreme conditions, making them perfect for demanding applications.

The process for ceramic bodies & shells steps:

The manufacturing process of ceramic bodies and shells is intricate, tailored to produce materials that can withstand extreme conditions.

This process ensures that the ceramic bodies and shells achieve the necessary mechanical, thermal, and chemical properties for their intended high-temperature applications.

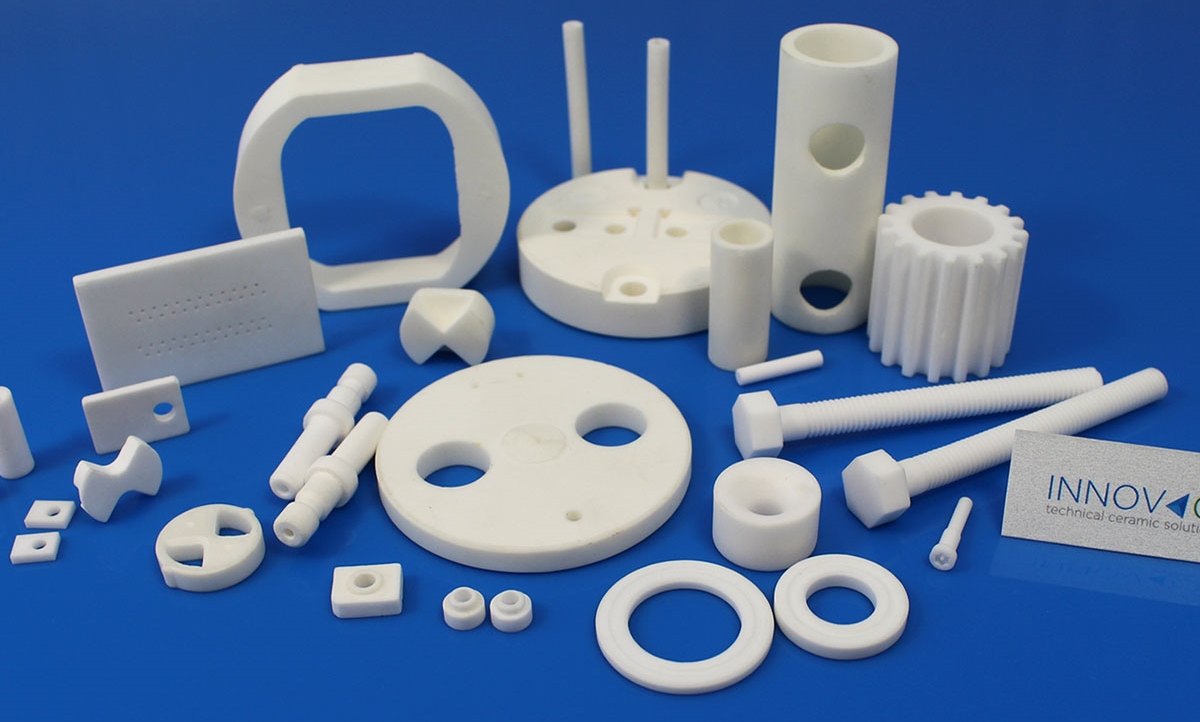

Examples of ceramic bodies & shells:

Ceramic bodies and shells are used in a wide array of applications, benefiting from their high-temperature resistance, strength, and chemical stability.

Kiln Furniture: Supports and shelves made of refractory ceramics used in kilns to hold and separate items during firing. They must withstand repeated heating cycles and support heavy loads at high temperatures.

Spark Plug Insulators: Ceramic shells in spark plugs provide electrical insulation and heat dissipation within internal combustion engines, withstanding extreme temperatures and corrosive environments.

Investment Casting Shells: Used in the precision casting process, these ceramic shells form the molds into which molten metal is poured, requiring excellent surface finish and dimensional stability at high temperatures.

Biomedical Implants: Ceramic bodies used in medical implants, like hip and knee replacements, offering biocompatibility, wear resistance, and stability in the human body.

Gas Turbine Components: Advanced ceramics are used in turbine blades and other components, providing resistance to thermal shock, high temperatures, and mechanical stress in jet engines and power plants.

Electrical Insulators: Ceramics serve as insulators in electrical applications, from simple household porcelain fuses to complex insulators in high-voltage power lines, due to their excellent dielectric properties.

Catalytic Converter Substrates: Ceramic bodies used as the support structure for catalytic materials in automotive catalytic converters, requiring high surface area and thermal shock resistance.

Tile and Sanitaryware: Ceramic bodies shaped into tiles, sinks, toilets, and other architectural elements, valued for their aesthetic qualities, durability, and ease of maintenance.

Wear-Resistant Linings: Used in industrial equipment like mills, mixers, and conveyors to protect against abrasion and corrosion, prolonging the lifespan of the machinery.

These examples demonstrate the versatility and essential role of ceramic bodies and shells in various sectors, including industrial, automotive, energy, medical, and consumer products.